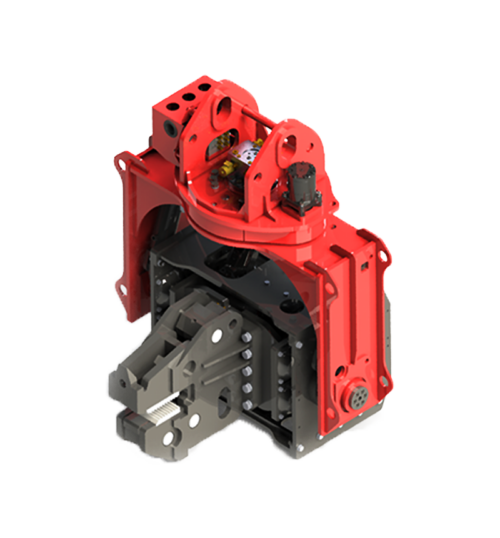

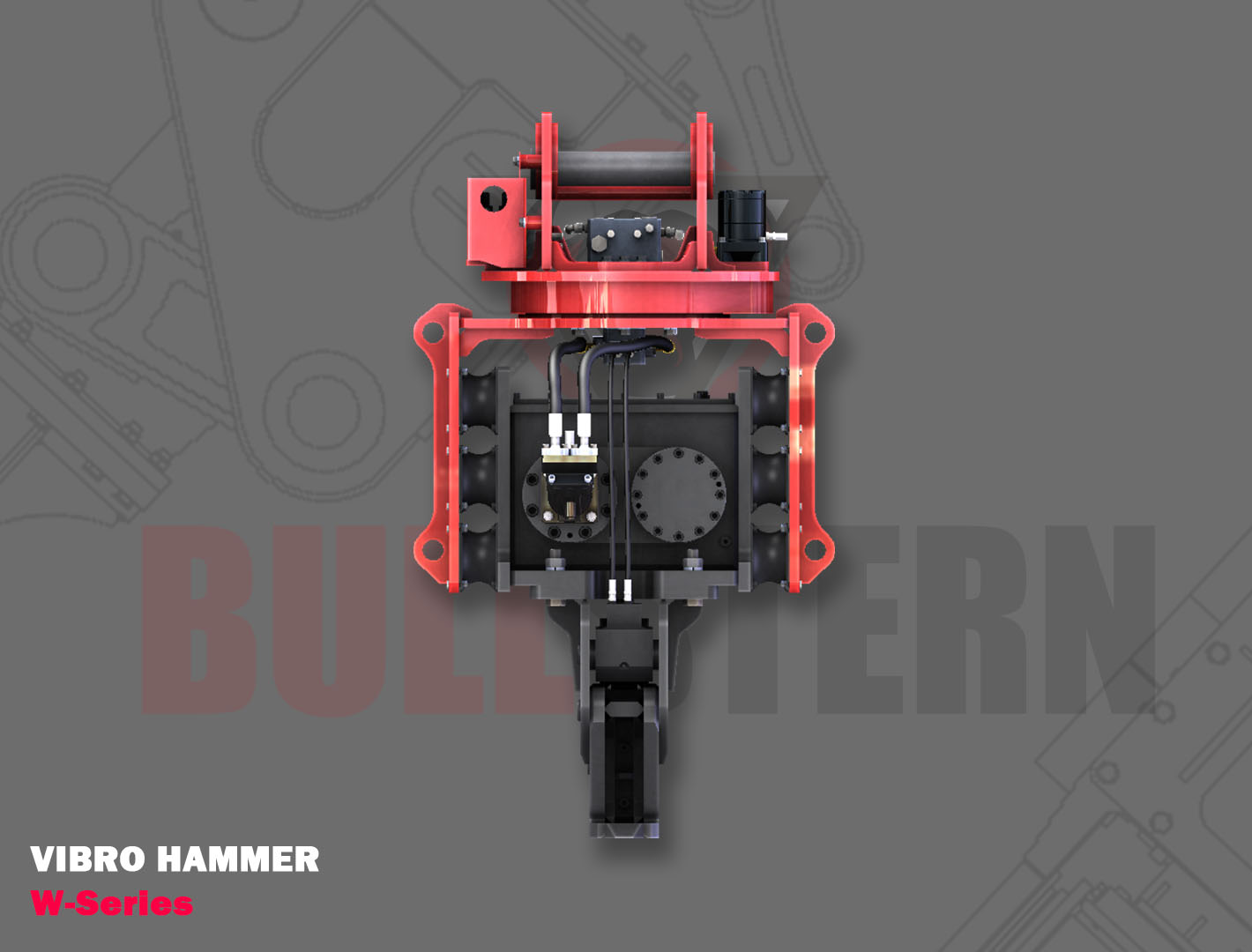

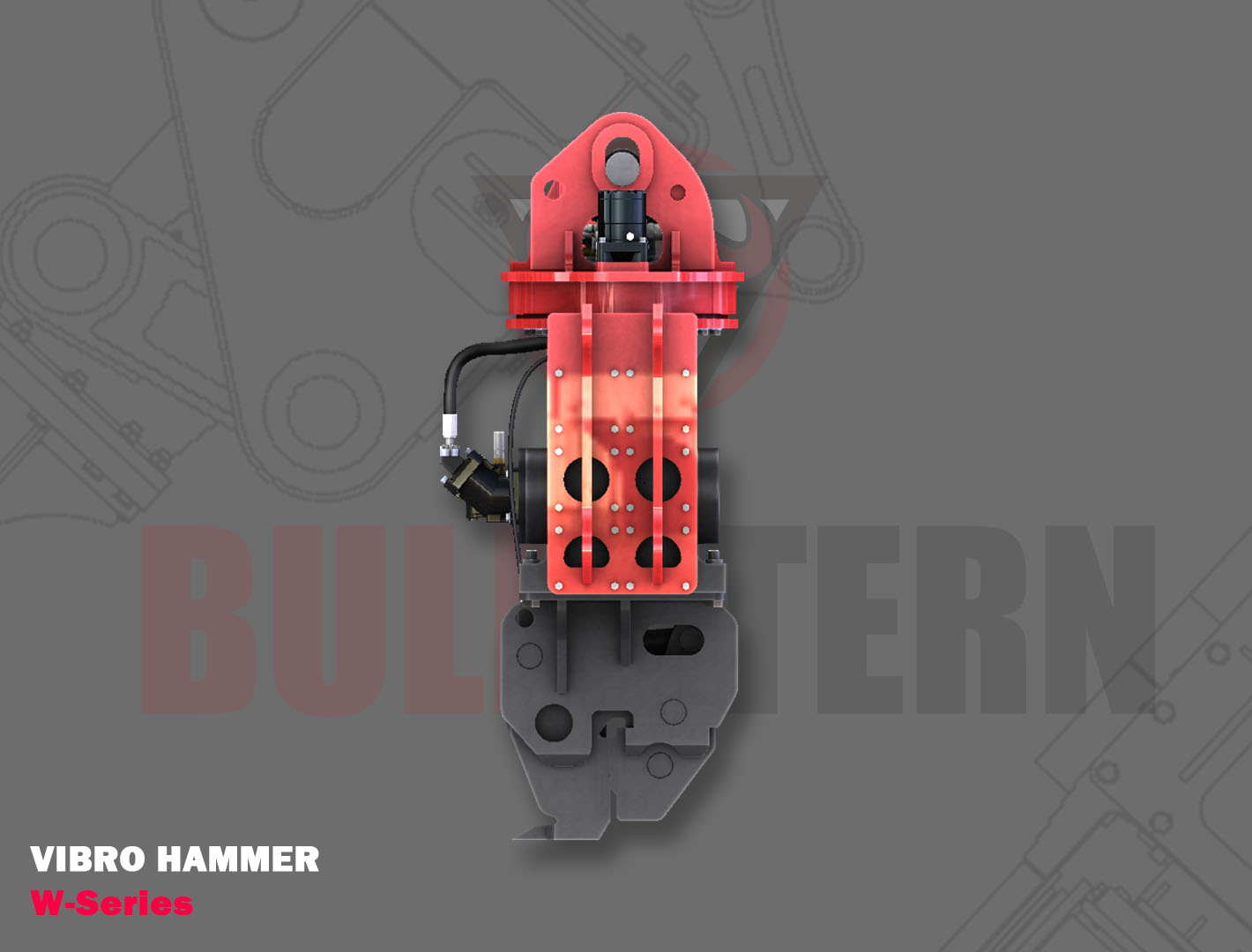

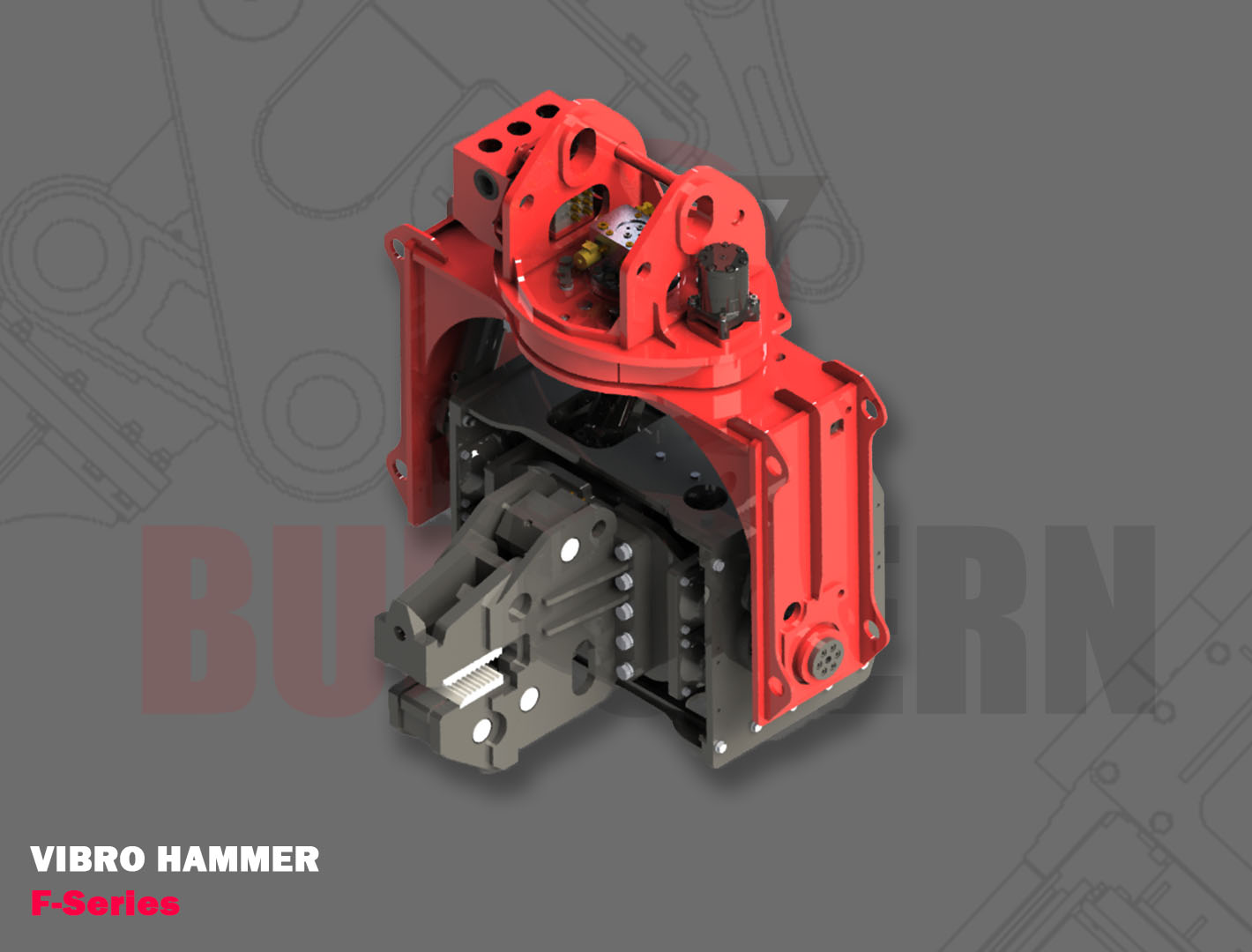

VIBRO HAMMER W/F-Series

TIME-EFFICIENT WITH LESS LABOR

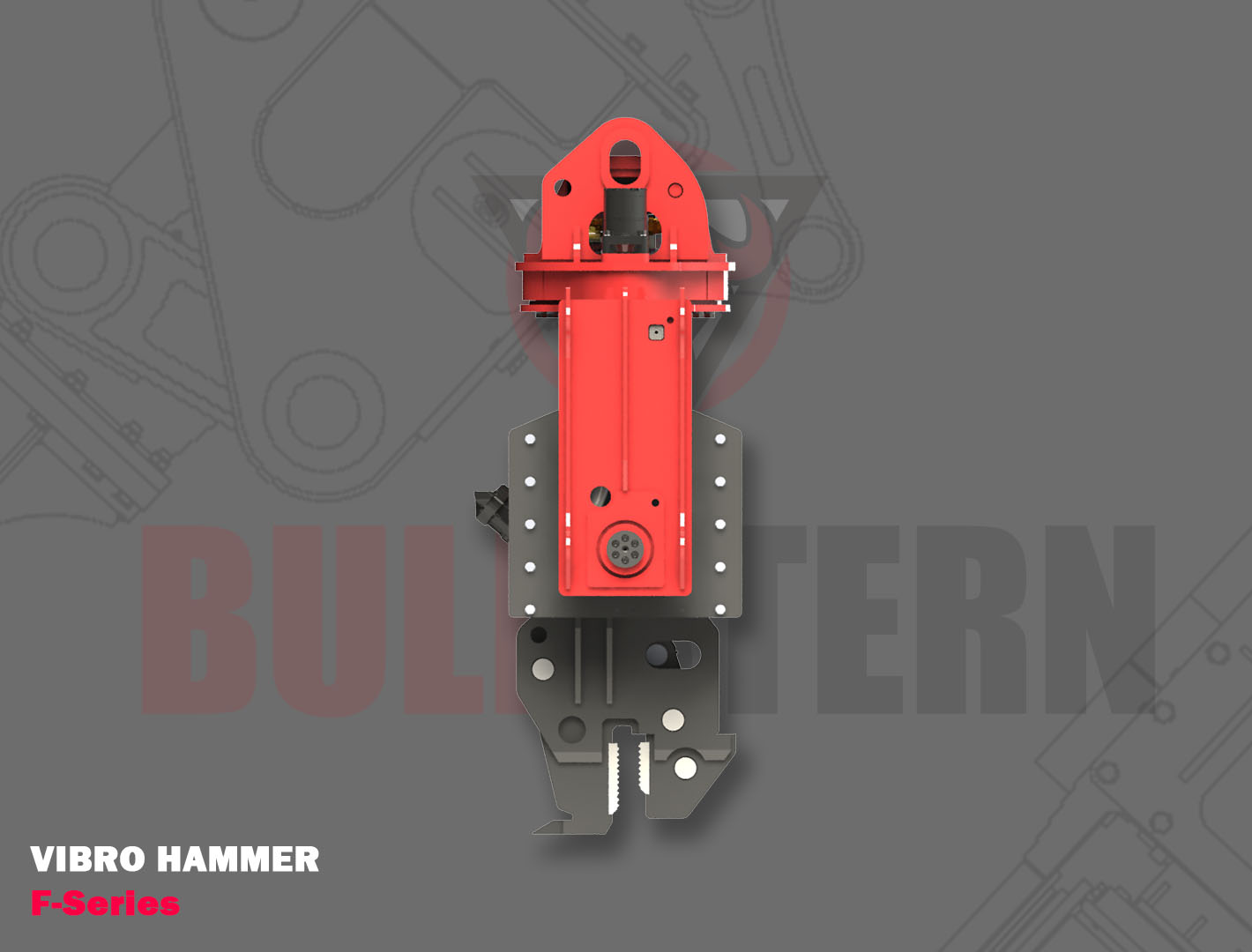

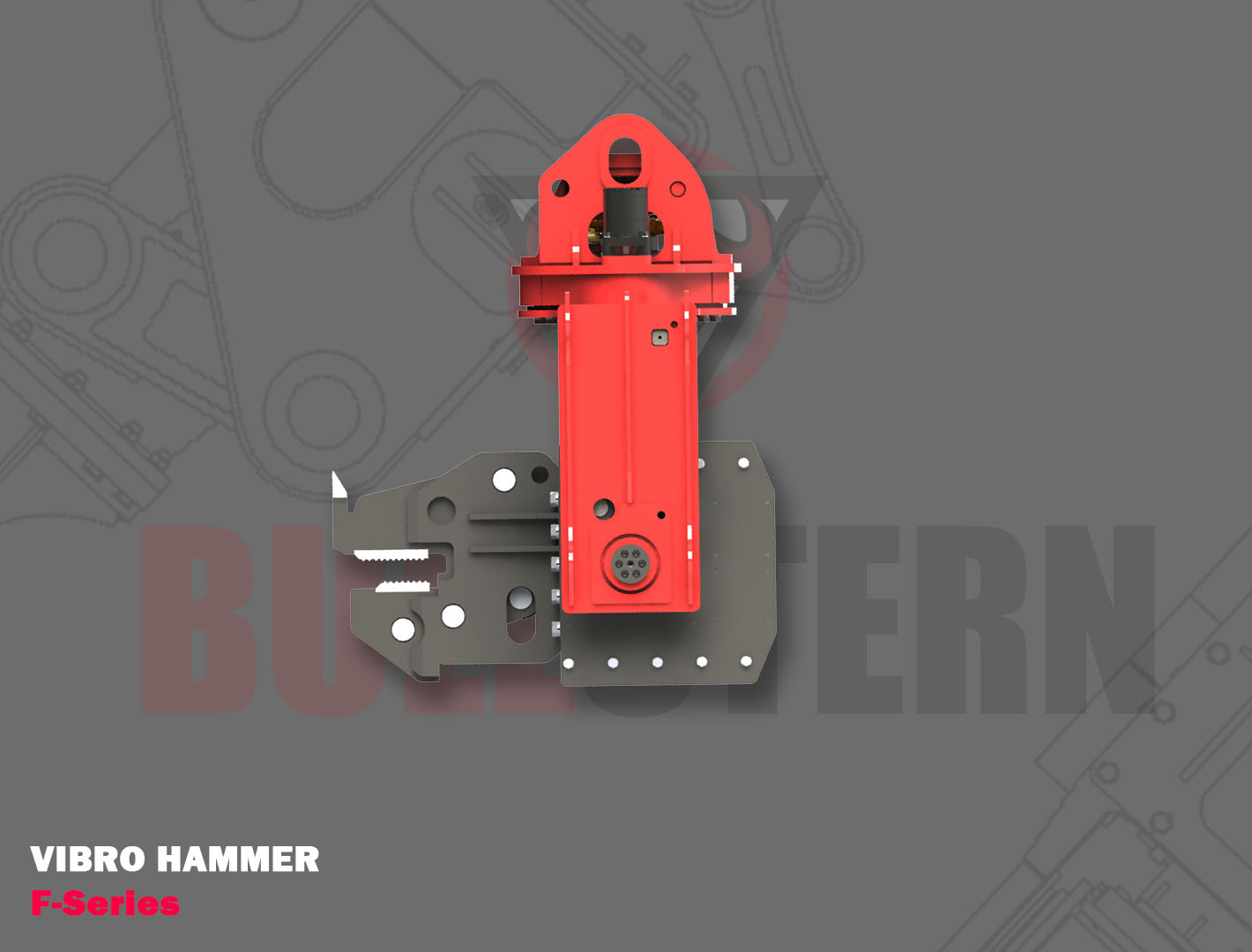

BULLSTER TILTING TYPE PILE DRIVER is the real time saver for pile driving jobs. With picking up a sheet pile in a horizontal position by 90-degree tilting function, the manual interference is reduced. In other words, almost nonstop piling operation is possible so that the operator is able to drive a sheet pile in a less cycle time than the basic type pile driver.

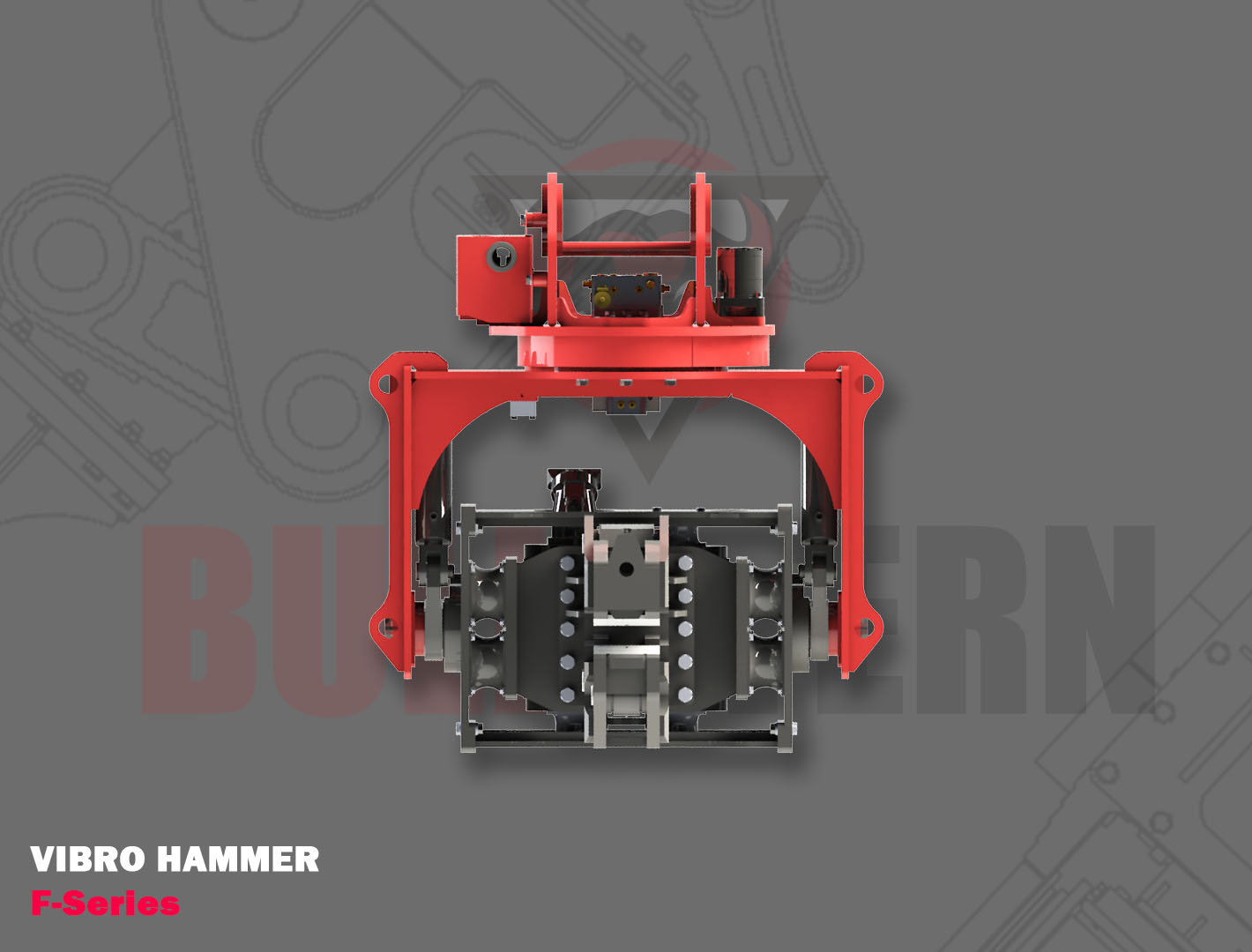

KEY BENEFITS (F-Series)

- High quality electrical harness

- 30% better efficiency than basic type

- Easy-clamping with no extra ground-level work

- Low-friction & long lasting cylinder

- 360-degree rotation / 90-degree tilting

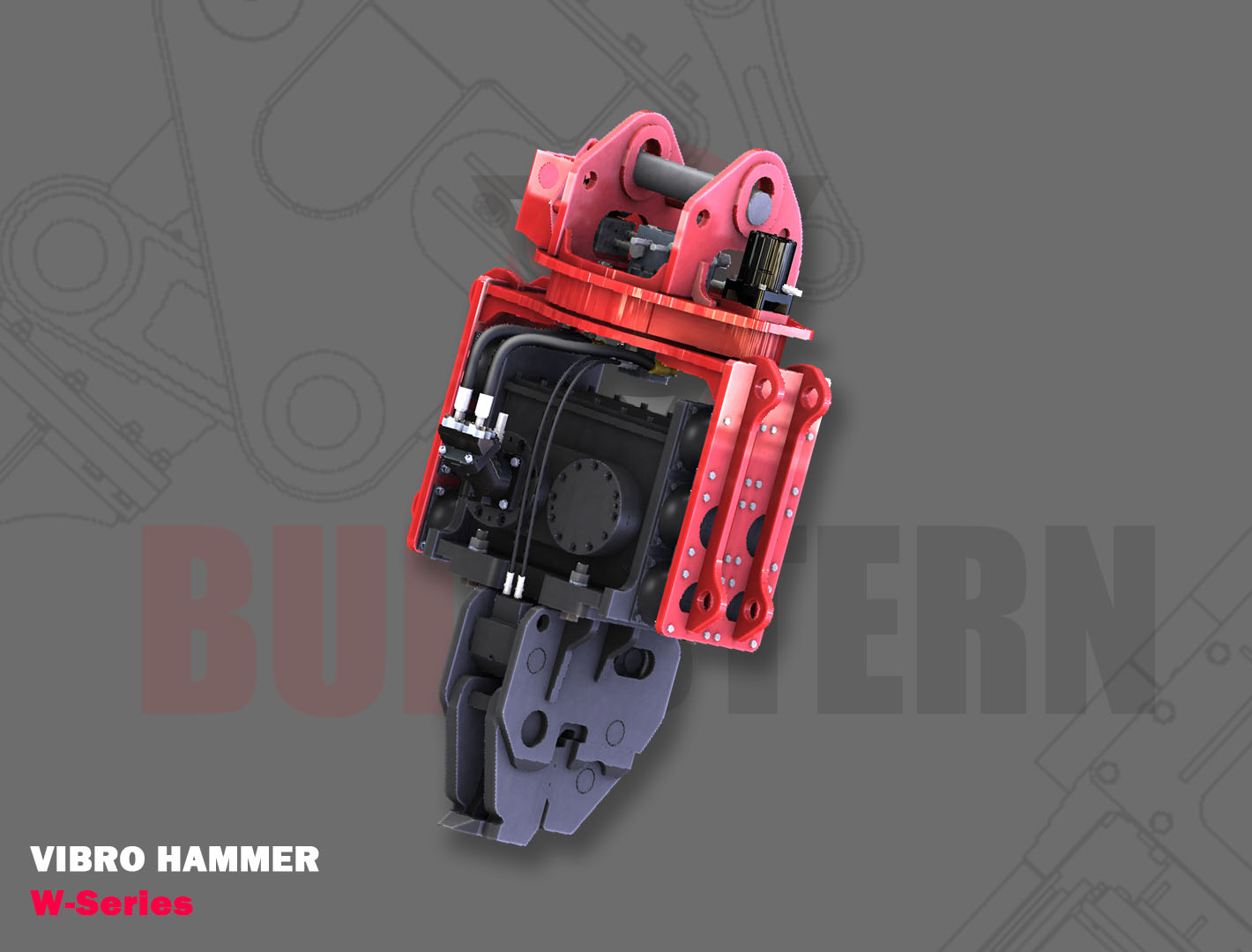

VIBRO HAMMER IN ACTION [W-Series]

VIBRO HAMMER IN ACTION [F-Series]

Why BULLSTERN Drives Faster: The Engineering Behind Superior Vibration Efficiency

1. Role of Centrifugal Force in Pile Driving

In vibratory hammer systems, efficient pile penetration depends on how effectively vibration energy is transferred from the hammer body to the tip of the pile.

The rotational motion of the eccentric mass generates centrifugal force, which becomes the primary source of this vibration energy.

Centrifugal Force Formula

Fc = m · r · ω²

Where:

- m = eccentric mass

- r = eccentric radius

- ω = rotational speed (angular velocity)

Centrifugal force increases proportionally with both the eccentric moment and the square of rotational speed. If either parameter—especially rotational speed—is insufficient, vibration transfer becomes inefficient, causing poor penetration and longer driving cycles.

2. BULLSTERN’s Engineering Approach

While many manufacturers prioritize increasing eccentric mass alone, BULLSTERN adopts a balanced approach focused on real-world operational efficiency.

Key design direction:

- Optimized combination of eccentric moment and high rotational speed

- Maximizing centrifugal force while ensuring stability and structural reliability

- Enhancing pile-driving performance without unnecessary increases in mass or housing size

This design philosophy delivers superior vibration output while maintaining component longevity under continuous high-speed operation.

3. Performance Characteristics of BULLSTERN Vibro Hammers

Higher Centrifugal Force Output

BULLSTERN hammers deliver up to 15% higher centrifugal force compared to typical models in the same class.

This allows faster penetration, effective energy transfer, and improved performance in stiff or cohesive soil conditions.

Durability at Elevated RPM

Internal structures—including bearings, shafts, and housing reinforcements—are engineered to withstand continuous high rotational speeds.

This minimizes premature wear and ensures stable output throughout the working cycle.

Efficient Vibration Transmission

The hammer design minimizes energy loss between the vibration source and the pile tip.

This results in consistent driving efficiency, reduced cycle time, and better handling of variable soil conditions.

Are You Looking for Reliable Attachment Manufacturer?

We Make Attachments Compatible with Almost All Excavators.